Buffalo Milking Liners vs Cow Milking Liners: What Every Dairy Farmer Should Know

When it comes to efficient milking, the liner is the heart of every milking machine. It’s the only part that directly touches the animal, so choosing the right one—whether for buffalo or cows—is crucial.

Many dairy farmers ask: “Can I use the same liner for both?” The truth is, buffalo milking liners and cow milking liners are not interchangeable. Let’s explore why.

The Biological Difference Behind the Liner Design

Buffalo and cow teats differ significantly in structure and milk let-down behavior:

- Buffalo teats are longer, thicker, and tighter, with a narrower teat canal. They require higher vacuum levels to start milk flow.

- Cow teats are shorter with wider canals, making them compatible with softer and shorter liners.

For instance, buffalo teat canals average around 24 mm, while cow teat canals are only about 10 mm long. This anatomical difference directly affects how each liner must be designed.

A milking machine is an automated system that efficiently extracts milk from cows or buffaloes using vacuum pressure and liners designed to ensure comfort and maximum milk yield.

How Buffalo Milking Liners Differ from Cow Milking Liners

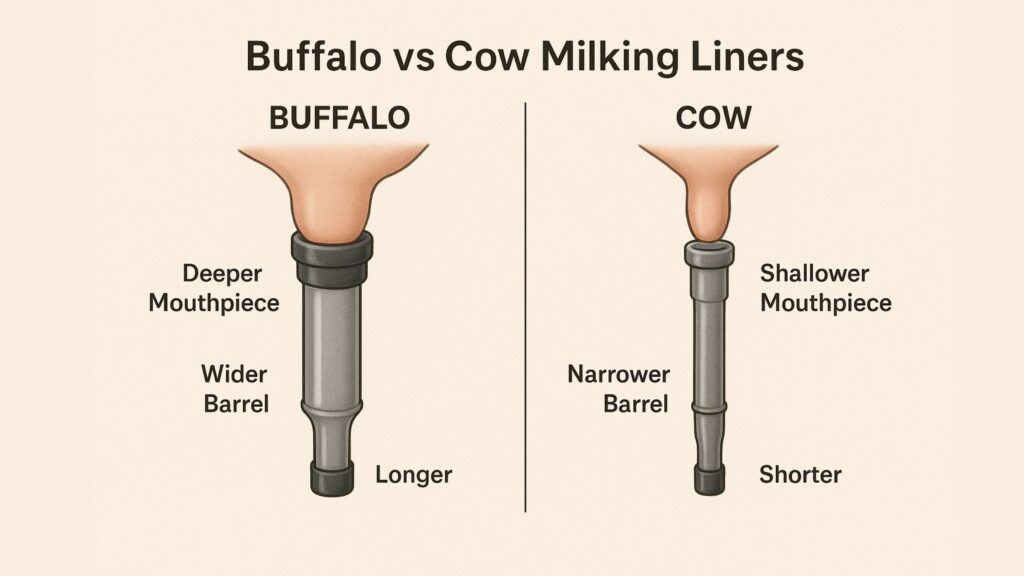

1. Mouthpiece Fit & Vacuum Control

The mouthpiece area of a liner must seal tightly but gently around the teat.

- Buffalo milking liners have deeper mouthpieces to suit longer teats and to control vacuum pressure effectively.

- Cow milking liners have shallower, smaller heads for a secure but gentle fit.

Poor fit can lead to congestion, liner slips, or incomplete milking—especially for buffaloes with tighter sphincters.

2. Barrel Diameter & Taper

Buffalo milking liners typically feature a wider barrel because buffalo teats are thicker.

A general rule: the barrel diameter should be 1–2 mm smaller than the herd’s average mid-teat width.

Cow milking liners, on the other hand, have a narrower barrel and varied taper options suitable for Holstein, Jersey, or cross-bred cows.

3. Liner Length & Collapse Zone

Buffalo teats are longer, so the liner’s collapse zone (the part that massages the teat) must align with the middle of the teat—not the tip.

Cow milking liners have a shorter effective length since their teats are shorter, ensuring consistent massage and milk flow.

4. Material & Cluster Weight

Buffalo milking liners are often made with stiffer rubber or silicone and paired with heavier clusters to stay stable on thicker teats.

Cow milking liners are lighter and more flexible, balancing speed and comfort during milking.

Example Specifications

| Type | Mouthpiece (mm) | Total Length (mm) | Designed For |

| Delmer Buffalo Milking Liner | 23 | 310 | Buffalo teats |

| Standard Cow Milking Liner | 20–25 | 120–170 | Dairy cows |

The Delmer buffalo milking liners are designed for the longer, thicker teats of buffaloes, while cow milking liners are optimized for shorter teat structures.

How to Choose the Right Milking Liner

- Measure teat diameters on at least 20 animals before milking.

- Pick a liner barrel 1–2 mm smaller than the average teat width.

- Choose a mouthpiece depth shorter than the teat length.

- Monitor for slips, colour changes, or congestion and adjust if needed.

Correct liner selection improves milk flow, prevents teat injury, and extends liner life.

Milking Settings for Best Results

Buffaloes store less milk in the udder cistern and depend on active let-down. Therefore, their machines must be tuned for:

- Proper stimulation before attachment

- Controlled vacuum levels

- Dual-level systems (like Duovac) to ease on/off phases

Cows, having a more spontaneous let-down, require less aggressive vacuum settings.

Key Takeaways

- Buffalo milking liners are wider, longer, and stiffer, suited for thicker teats and stronger vacuum systems.

- Cow milking liners are shorter, narrower, and softer, designed for gentle milking and fast throughput.

- The right liner ensures better milk yield, healthier teats, and longer equipment life.

Whether you’re running a mixed herd or a specialized dairy, choosing the correct liner type is the foundation of efficient and animal-friendly milking.

for more information visit delmergroup.com